SAFETY AND EFFICIENCY

Digitization and control of gas distribution networks

Energy saving systems

The need to ensure networks’ safety and efficiency, has always kept the gas sector in Italy one of the most aware of the importance of maintenance and technological advancement.

The goal today is to achieve an efficiency system for the management of the plants, odorization and pre-heating systems as well as lowering the risk of anomalies and accidents.

The latter are factors on which control and automation systems play a leading role, managing to guarantee operational safety while also allowing for energy savings from 30% up to 70%.

ASW-ATI creates the SCADA and CLOUD control center able to control and regulate the entire distribution network, from the first jump cabins to the second jump booths, up to the bottom of the network.

Efficiency and safety throughout the gas network

MANAGEMENT

-

SCADA

Control center

-

VIDI CLOUD

Services

IPRM/REMI

HECOS

HEating COntrol System

- mains-powered RTUs

GRF/GRI/IRI

- mains-powered RTUs

- battery-powered RTUs

Termination point

- battery-powered RTUs

Monitoring and control of the whole process:

- Reduction in gas consumption

- Reduction of operating costs

- Energy saving

- Management of alarms and anomalies

Monitoring:

- Reduction section

- Preheating system section

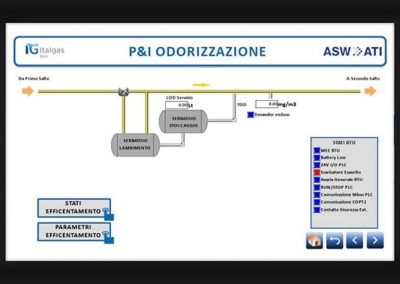

- Odorisation section

- Cathodic protection

- Consumption

Control:

- Active pressures management

- Thermal power station management

- Cathodic protection power supply management

Monitoring:

- Reduction section

- Cathodic protection

- Odor level

Control:

- Active management of pressures

Monitoring:

- Pressure measurement

MANAGEMENT

- SCADA Control center

- VIDI CLOUD Services

IPRM/REMI

HECOS

HEating COntrol System

- mains-powered RTUs

Monitoring and control of the whole process:

- Reduction in gas consumption

- Reduction of operating costs

- Energy saving

- Management of alarms and anomalies

Monitoring:

- Reduction section

- Preheating system section

- Odorisation section

- Cathodic protection

- Consumption

Control:

- Active pressures management

- Thermal power station management

- Cathodic protection power supply management

GRF/GRI/IRI

- mains-powered RTUs

- battery-powered RTUs

Termination point

- battery-powered RTUs

Monitoring:

- Reduction section

- Cathodic protection

- Odor level

Control:

- Active management of pressures

Monitoring:

- Pressure measurement

MANAGEMENT

- SCADA Control center

- VIDI CLOUD Services

Monitoring and control of the whole process:

- Reduction in gas consumption

- Reduction of operating costs

- Energy saving

- Management of alarms and anomalies

IPRM/REMI

HECOS

HEating COntrol System

- RTU alimentate da rete elettrica

Monitoring:

- Reduction section

- Preheating system section

- Odorisation section

- Cathodic protection

- Consumption

Control:

- Active pressures management

- Thermal power station management

- Cathodic protection power supply management

GRF/GRI/IRI

- mains-powered RTUs

- battery-powered RTUs

Monitoring:

- Reduction section

- Cathodic protection

- Odor level

Control:

- Active management of pressures

Termination point

- battery-powered RTUs

Monitoring:

- Pressure measurement

Natural gas distribution networks are simple and intrinsically robust – thanks to mechanical and pneumatic equipment that delivers gas to final users without the aid of electricity.

However, from the point of view of management, they require the adoption of the maximum level of safety and efficiency.

Our solutions are designed to give the operator immediate and easy access to monitoring and control functions.

Control center

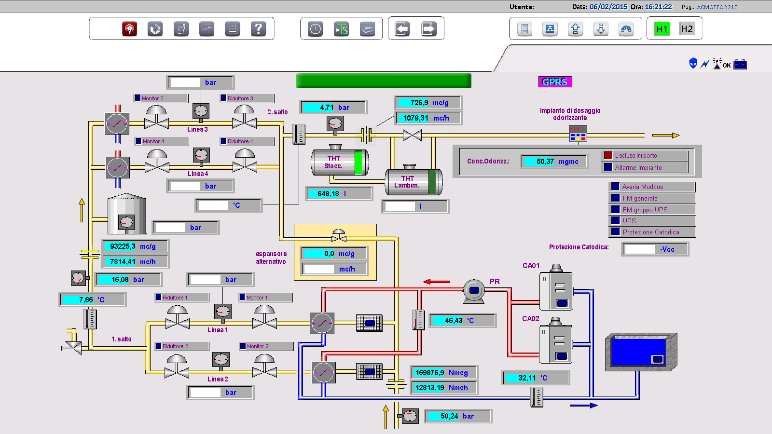

All data flows into the control center, based on the SCADA platform for monitoring and centralized control of the entire process.

Alarms are managed locally and allow you to alert people on call. There are also historical relational and system databases, graphic analysis of both historical and real-time trends and reports. In addition, you can activate VIDI CLOUD services, to have easy access to information from any fixed or mobile device. These services also include notification of alerts in real time on iOS and Android Apps, with advanced management of on-call and shift settings.

The power of Cloud services also allows to:

- Geolocate the information

- Checking RTU status

- View the process variables status

- View historical data

- Analyze and aggregate data

- See dashboard and KPI

Our application experience on water networks has enabled us to meet the challenges set by this sector.

Based on an industrial PLC, HECOS combines the classic monitoring functions of an RTU, with the control and control functions, typical of industrial automation.

FEATURES

- Control of the thermal power plant (boilers and recirculation pumps)

- Active control of the reduction stage

- Control of the odorization system

- Active monitoring and control of the cathodic protection system

Focus on HECOS

HEating COntrol System

RTU for IPRM/REMI cab control

This RTU, located in the IPRM cabin, it manage the plant safely, optimizing the preheating process.

Its lightweight and self-adaptive algorithm allows it to operate in any type of cabin, from the oldest to the most advanced.

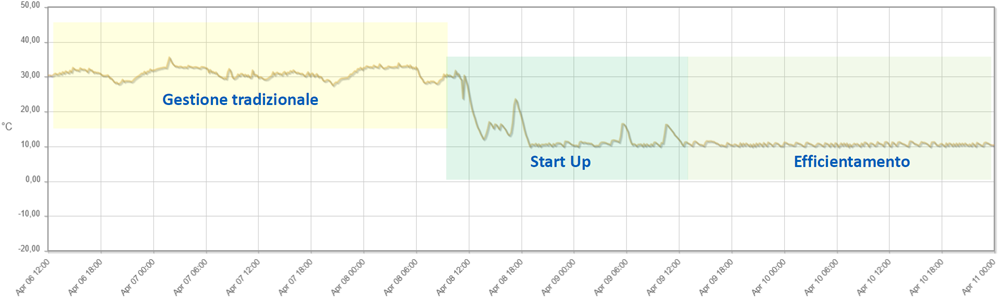

The benefit is almost immediate, in the graph below it is possible to observ a comparison before and after the installation of our RTU.

Monitoring of the temperature of the gas leaving the plant before and after HECOS ignition

-

Gas savings for the preheating process

-

Saving electricity in pump management

-

Reduction of CO2 emissions

TOTAL ENERGY SAVINGS BETWEEN 30% AND 70%